The unique climate and demands faced by Australian farmers have seen the birth of contraptions, inventions and innovations which not only solved problems here but went on to be adopted worldwide. It’s a rich heritage which has yielded dozens of technical breakthroughs, but we’ve narrowed them down to a showcase of the inventions that made the most impact on farmers here and overseas.

HEADER HARVESTER

Immortalised in bronze at Henty, Headlie Taylor is recognised as the inventor who revolutionised grain harvesting. While there were already machines capable of stripping grain from standing wheat, Taylor’s design enabled farmers to harvest crops flattened by storms. His idea was to lift the damaged wheat with a long-fingered comb fitted with reciprocating knives, which would cut the stalks and feed the wheat up an elevator to a thresher. It’s a method replicated in nearly all modern combine harvesters. Three of his new machines were made under licence in 1915, starting a boom which has seen Headlie recognised as Australia’s greatest ag machinery revolutionary.

RIDLEY STRIPPER

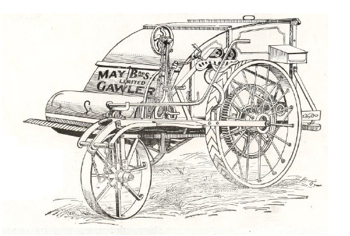

RIDLEY STRIPPER

Before Headlie’s Header Harvester, Australian farmers had been stripping grain from wheat stalks from the mid-19th century. The stripper harvester was invented by John Ridley, an English immigrant who farmed wheat in South Australia after arriving in 1839. He developed a machine pushed by two horses through a crop, stripping the grain and collecting it in a hopper. Instantly popular, thanks to a lack of labour in the state at the time and the fact it kept the crop dry so export quality was high, the Ridley Stripper earned its inventor a good income. But some historians credit its inventor as John Wrathall Bull, even though it’s beyond dispute that Ridley was the first to put it to work.

SUNSHINE HARVESTER

Hugh Victor McKay sits between Ridley and Taylor in the combine harvester development timeline as having successfully invented a machine capable of harvesting, threshing and winnowing wheat. While working on his family farm, the boy from Drummartin (he was 19 at the time) read about combine harvesters being developed in the US. He put some ideas together and built what became known as the Sunshine Harvester in 1885. He wasn’t the only one. James Morrow came out with the same idea that year and won a government prize for it, but McKay had better business sense and his machine went on to be a commercial success.

WOLSELEY SHEARING MACHINE

WOLSELEY SHEARING MACHINE

Sheep stations were frantic hubs of activity at shearing time with up to 20 men cutting the wool from the backs of 50,000 sheep with hand shears. It was arduous work and not much fun for the sheep, who were routinely stabbed and sliced with the razor-sharp, scissor- like shears. NSW farmer Frederick Wolseley came to the rescue with the first ever mechanical shearing machine, which was very much like the hair clippers of today, with knives above a comb moving side-toside to cut the wool. Power was originally generated by a horse gin connected to a belt and pulley which rotated a shaft that ran the length of the shearing shed. A wheel at each shearing bay drove a length of sheep gut at 1600rpm within a leather pipe which ran to the shears. It totally revolutionised shearing, allowing for much better-quality fleeces shorn from the backs of much happier sheep by shearers who could mow through more than ever before.

GYRAL AIR SEEDER

A particularly wet 1956 season in Dalby, Queensland prompted broadacre farmer Albert Fuss to try something new to get seed in the ground. At the ripe old age of 68, Fuss sought a solution to handling the compacted soil and trash which the combine drills of the time were struggling with. His son Roy later said: “My father came up with a lightweight air seeder which could be mounted on to a chisel plough, plus it had the added bonus of handling all types of cereals.” Immediately seeing its potential, the family applied for a patent that year, making the Gyral the first commercial broadacre air seeder in the world. The name came from the gyroscopic action of the spinner at the bottom of the seed hopper. The spinner would blow the seed down a hose to the furrow just behind the tyne which tore through the hard ground. Such was its success that the family went into the engineering business and Gyral air seeders are still produced today.

STUMP-JUMP PLOUGH

The expression “tough as a Mallee root” may well have been coined by farmers trying to get a plough through ground cleared of the stubby eucalypts in Victoria, South Australia and southern NSW in the mid-19th Century. The roots left in the ground were gnarly, rock-hard and difficult to budge, and the furrow ploughs of the time did not enjoy unexpected encounters with them. Money was offered to anyone who could come up with an effective way to get rid of the stumps but that had limited results. Richard Bowyer Smith thought outside the square and in 1876 developed a plough capable of skipping over the stumps then re-engaging the ground. Hinged ploughshares (the part behind the chisel at the tip of the plough blade) rode over the stump and were then driven back into the ground with weights. Smith’s invention, the Stump-Jump Plough, revolutionised crop farming in rough ground and is still recognised as one of the most important agricultural breakthroughs of all time.

HARRINGTON SEED DESTRUCTOR

HARRINGTON SEED DESTRUCTOR

Dealing with weeds is a $3.23 billion headache for Australian broadacre farmers because the herbicides used to control them are expensive and lose their effectiveness

over time. Numerous alternatives to chemical treatment have been trialled over the decades, but a Western Australia farmer created a method which is gathering international interest. Ray Harrington created a way of crushing weed seeds as they exit the combine harvester, rendering 95 per cent of them incapable of germinating. The seeds are in the chaff which is usually blown out the back of the harvester leaving a trail of potential new weeds. Harrington’s invention is a cage mill with rotating metal blades which smash the seeds as they are pushed through with the chaff. Originally the Harrington Seed Destructor, as it was dramatically named, was a cart towed behind the harvester, but it has since been redesigned to mount on the machine. It’s getting interest from the US and Canada for its potential to save farmers millions.